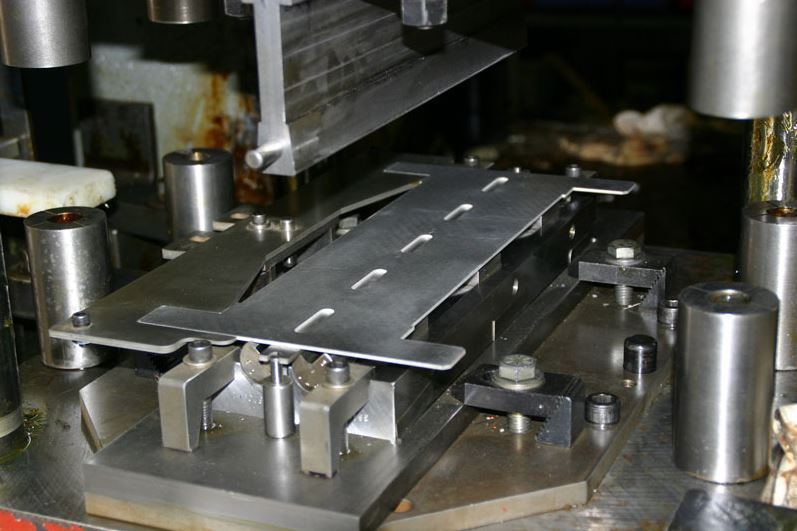

(1) The stamping process has high production efficiency and is easy to operate, and is easy to mechanize and automate. This is because the stamping relies on die and stamping equipment to complete the processing. The number of strokes of ordinary presses can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute, and each press stroke is Maybe get a punch.

(2) Since the die guarantees the size and shape accuracy of the stamping part during stamping, and generally

does not damage the surface quality of the stamping part, and the life of the die is generally long, the quality of the stamping is stable, the interchangeability is good, and it has “the same”. Characteristics.

(3) Stamping can process parts with large size range and complex shape, such as the second hand from small clocks, to the longitudinal beam of the car, the cover, etc., plus the cold deformation hardening effect of the material during stamping, the strength of the stamping and The stiffness is high.

(4) Stamping generally has no chip scraps, less material consumption, and no need for other heating equipment. Therefore, it is a material-saving and energy-saving processing method, and the cost of stamping parts is low.

TERADA HARDWARE

TERADA HARDWARE