How to Use Rigging Hardware Wire Rope Clip?

Precautions for use of the wire rope clips: it cannot be used for a long time, it should be inspected and scrapped regularly, and it cannot be used repeatedly.

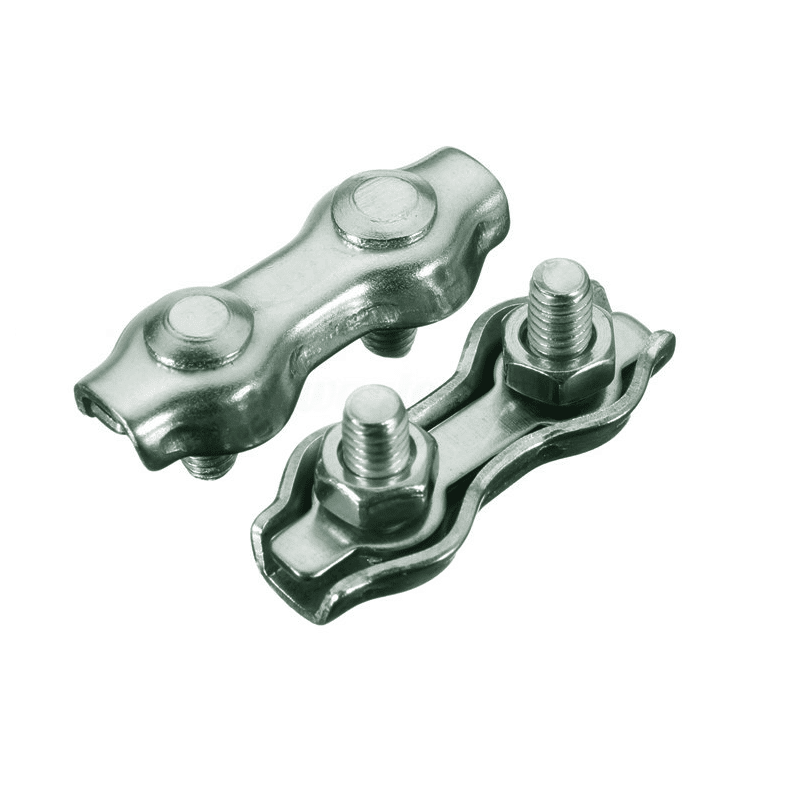

(1) The size of the wire rope clamp should be suitable for the thickness of the wire rope. The inner clearance of the U-shaped ring should be 1 to 3 mm larger than the diameter of the wire rope. If the clear distance is too large, the rope cannot be clamped easily.

(2) When in use, tighten the U-bolt until the wire rope is flattened by about 1/3. As the steel wire rope deforms after being stressed, the rope must be tightened a second time after the steel wire rope is stressed to ensure the joint is secure. If it is necessary to check whether the rope card is slipping after the wire rope is stressed, an additional safety rope card can be used for this. The safety rope card is installed about 500mm from the last rope card. After releasing the rope head for a safety bend, it is clamped with the main rope. If the clip slips, the safety bend will be straightened, which is easy to find and reinforce in time. .

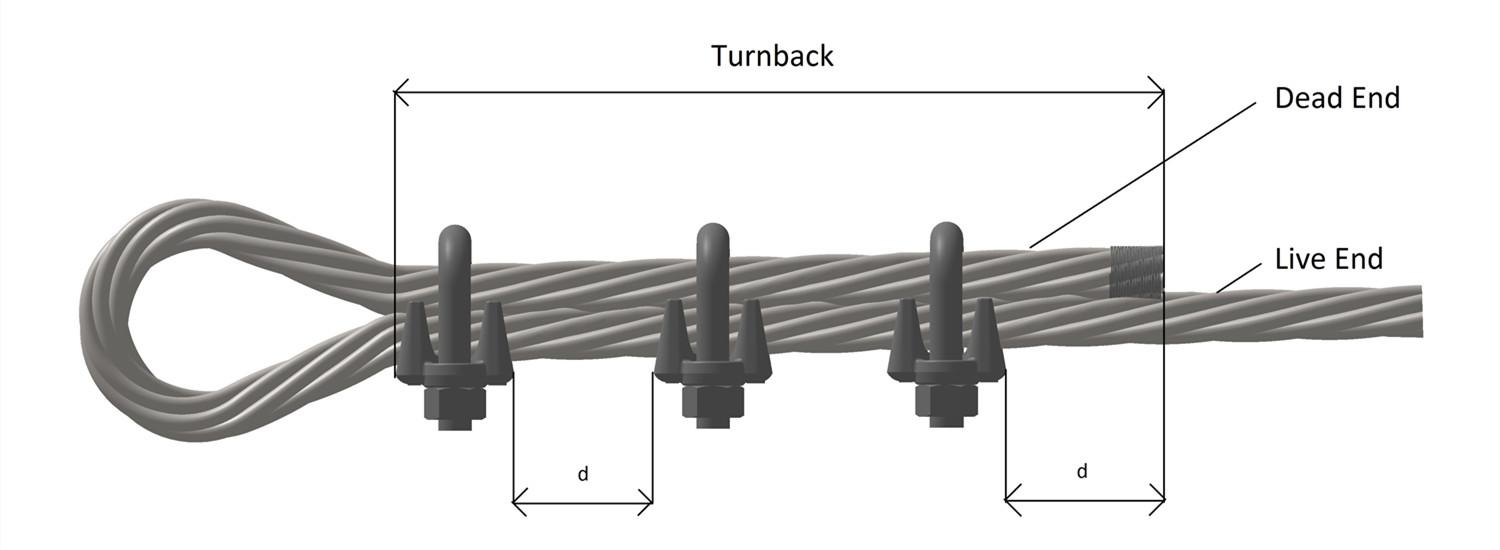

(3) The arrangement interval between rope cards is generally about 6 to 7 times the diameter of the wire rope. The rope cards should be arranged in order. The U-shaped ring should be clamped on the side of the rope head, and the pressure plate should be placed on the side of the main rope.

(4) Correctly arrange the quantity and method:

The number of rope clips is generally not less than 3-5. The spacing between rope clips should be ≥ 6 times the wire rope warp. The distance between the last clip and the rope head should be ≥140mm.

There are 3 ≤18mm,

18-26mm set of 4,

26-36mm set of 5,

36-44mm with 6

44-60mm set of seven.

(5) Wire rope rope clamp should be used together. When the rope diameter is below 19mm, the rope clamp should not be less than 3, and 19-32mm should not be less than 4. The arrangement interval between rope clamp is generally about 6 to 8 times the diameter of the wire rope. To arrange the rope clamp in order, the U-shaped ring should be clamped on the side of the rope head, and the pressure plate should be placed on the side of the main rope.

After the wire rope clip is loaded once or twice, it should be checked for looseness. In general, the nuts need to be tightened further.

(6) Pay attention to the following two points when using:

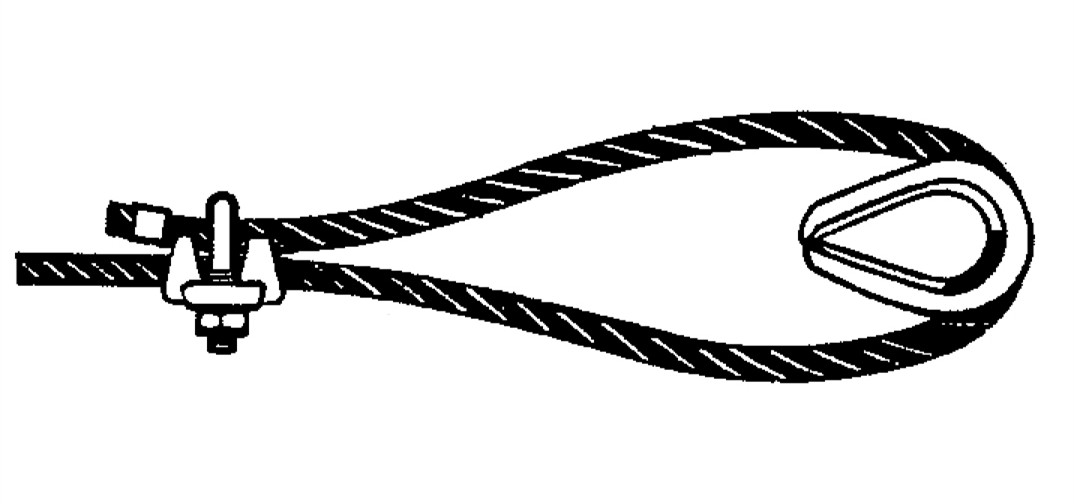

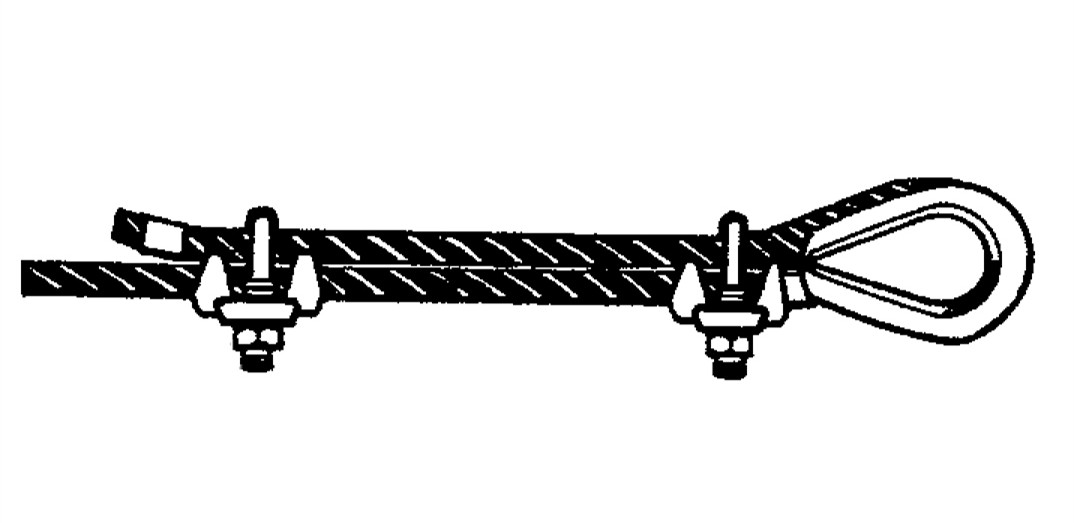

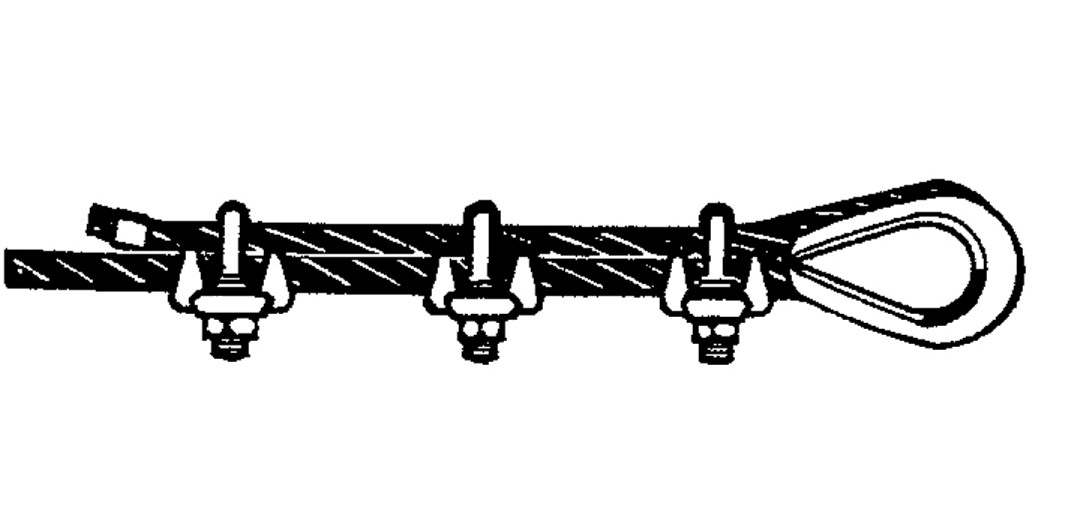

a) The size of the clamp should be suitable for the thickness of the wire rope. The inner clearance of the U-ring should be 1-3mm larger than the diameter of the wire rope. If the clear distance is too large, the rope should not be clamped, which is prone to accidents. b) Be sure to tighten the bolts when tightening the chucks until the rope is flattened by 1 / 3-1 / 4 diameter. After the rope is stressed, tighten the chuck bolts again to ensure the joint is firm and reliable. c) The chucks should be arranged in a straight line. The U-shaped part should be in contact with the rope head and not the main rope, as shown in Figure a. If the U-shaped part is in contact with the main rope, after the main rope is squashed, the force is easy to break.

d) In order to easily check whether the joint is reliable and find out whether the wire rope is sliding, you can press another chuck about 500mm behind the last clip and release the rope head with a "safety bend". As shown in Figure b. In this way, when the wire rope of the joint slips. The "safety bend" was first straightened, and measures should be taken immediately.

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

TERADA HARDWARE

TERADA HARDWARE