How To Install Wire Rope Clamp with cable?

How To Install Wire Rope Clamp with cable?

The purpose of the wire rope clamp:

First, stainless steel casting wire rope clips are commonly used for static bolting, rope cable fastening, such as power, communication lines, strapping and fastening.

Forged steel wire rope clamps are often used for lifting and lifting load, such as various engineering lifting machinery, metallurgical mining equipment, oil field derrick, port railway loading and unloading, forestry machinery, electrical equipment, aviation and marine, land transportation, engineering rescue, salvage shipwreck , factory and mining enterprises lifting, hoisting, traction rigging.

Stainless steel wire rope clips are used in marine fittings, chemical plants, radiation, etc. due to their corrosion resistance and rust resistance.

Second, the characteristics: with the strength of the wire rope, the use of safety, the appearance of the beautiful transition smooth, lifting work safety load, can withstand the impact load, long service life.

Wire rope clamp method and standard of use:

1. When using the stainless steel clamp, it must be used in conjunction with the diameter of the wire rope.

2. In order to protect the wire rope from wear, the top eye must in principle use a wire rope collar.

3. At the end of each wire rope, three or more chucks should be used at the same time to obtain effective locking force. The spacing of each rope clamp should be 6-7 times the diameter of the wire rope.

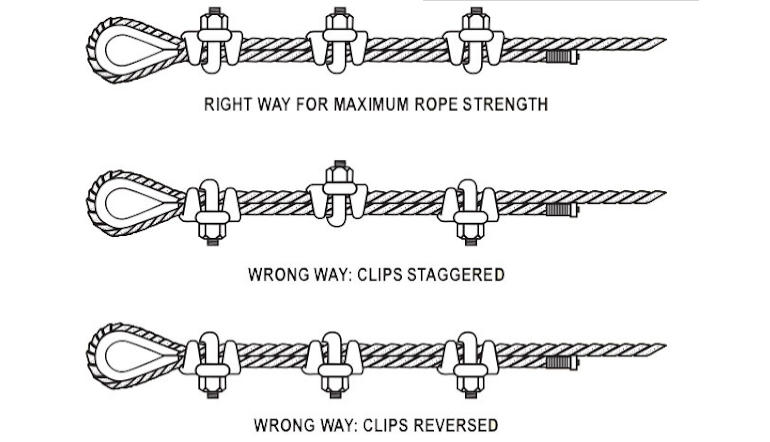

4. The wire rope clamp should be fastened to the working section of the wire rope. The U-shaped bolts are fastened on the tail section of the wire rope and should not be alternately arranged on the wire rope, as shown in the following figure:

5. It is necessary to consider the reasonable force of each rope clamp to fasten the rope clamp. The rope clamp farthest from the collar shall not be separately fastened first. The rope clamp (the first rope clamp) closest to the collar should be as close as possible to the collar, but the rope clamp must be properly tightened and the outer wire of the rope must not be damaged.

6. The strength of the wire rope clamp is determined by the correct arrangement of the rope clamp on the wire rope and the caution and proficiency of the rope clamp fixing and clamping. Insufficient tightening of the nuts or wire rope clamps may cause the rope ends to slip when initially loaded. If the rope clamps are properly arranged and tightened according to the recommended number, and all the rope clamps will clamp the longer part of the rope, and the U-bolts are to the shorter or tail section of the rope, then the strength of the fixing is at least 80% of the strength of the wire rope itself. In the actual use, the clamp rope should be inspected after being loaded one or two times. In most cases, the nut needs to be further tightened.

7. Stainless steel wire rope clamps are prone to lock-up due to stainless steel fasteners. When tightening nuts, the nuts should follow the anti-locking method of stainless steel fasteners. If necessary, use diesel or anti-locking oil for pretreatment.

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

subscription

NAVIGATION

LATEST POSTS

TERADA HARDWARE

TERADA HARDWARE